Adjustable outer cone measuring tool

Uniquely focused on computers and related products, Micro Center offers more computers and electronic devices than any other retailer. Micro Center is deeply passionate about providing product expertise and exceptional customer service. The Manfrotto XPRO 3-Way Geared head is a lightweight and portable solution for advanced hobbyists looking for maximum precision from a photographic head. The current study evaluated prosthetic dental crowns obtained by optical scanning and a computer-aided designing/computer-aided manufacturing system using micro-computed tomography to compare the marginal fit. The virtual models were obtained with four different scanning surfaces: typodont (T), regular impressions (RI), master casts (MC), and powdered master casts (PMC). Five virtual models.

Aug 27, 2010 Started in 1988, MicroMetric is celebrating our 22nd year of serving the computer needs of Sarasota and Manatee County Small Businesses. Micrometric Ltd 235 followers on LinkedIn. Component manufacturer and laser processing specialist producing high-quality fast turn-around components. Founded in 1981 in Lincoln, Micrometric Ltd specialises in the laser material processing of metals. We are a European leader in the use of lasers which produce fine parts and precision components for small prototypes through to large scale.

Download PDFInfo

- Publication number

- CN201193943Y CN201193943YCNU2008200209286UCN200820020928UCN201193943YCN 201193943 YCN201193943 YCN 201193943YCN U2008200209286 UCNU2008200209286 UCN U2008200209286UCN 200820020928 UCN200820020928 UCN 200820020928UCN 201193943 YCN201193943 YCN 201193943Y

- Authority

- CN

- China

- Prior art keywords

- contact terminals

- adjustable

- Chinese (zh)

- Inventor

- 王卫东

- 程钢

- Priority date (The priority date is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the date listed.)

- Filing date

- Publication date

- Critical程钢

- Criticalpatent/CN201193943Y/en

- Critical

- Criticalpatent/CN201193943Y/en

- claimsdescription4

- claims238000005516engineering processesMethods0.000230000002950deficientEffects0.000230000000694effectsEffects0.000238000007429general methodsMethods0.000238000003754machiningMethods0.000238000000034methodsMethods0.000Technical field

The utility model relates to a kind of survey instrument, specifically a kind of adjustable outer cone survey instrument.

Background technology

In machining, often need to measure the intended diameter D of processing parts outer conical surface and the actual error value of d, cone angle and shape of generatrix etc.Want to process qualified circular conical surface, a kind of convenient bevel protractor or gauge of accurately measuring the circular conical surface tapering that can be used at first will be arranged.But, because going up near the structure of circular conical surface, axle limits, existing bevel protractor or Mohs awl gauge are difficult to even can not accurately measure the taper value of circular conical surface on the shaft.General method commonly used is diameter and the length of element of cone or the length of circular cone with milscale or vernier caliper measurement circular conical surface two ends, calculate the tapering of circular conical surface again according to these data, the taper value error of calculating like this is bigger, and reason is end diameter indeterminacy really (because cylindrical is the inclined-plane herein).Because the circular conical surface indeterminacy of grinding is true, so be difficult to guarantee the precision of the processed conical surface.Influence the workpiece processing quality.For this reason, design a kind of specific purpose tool, satisfied the needs that cone shape is measured.

The utility model content

Technical problem to be solved in the utility model provide at the existing in prior technology defective a kind of simple to operate, cost is low is used for the cone shape survey instrument.

The technical scheme that its technical matters that solves the utility model adopts is: a kind of adjustable outer cone survey instrument, and its structure comprises support, framework, supporting contact, collet, clock gauge, guidance contacts, micrometer, L shaped armed lever; Two knife edge contacts and two guidance contacts with spline structure are arranged on the framework in support, and guidance contacts is installed in and supports contact and become 90 ° side, and the ratio of two guidance contacts mounting distances and difference in height and the installation of supporting contact are consistent; Clock gauge is fixed on the framework by collet.

Described framework two ends are connected with the micrometric screw parts, and micrometric screw acts on the both ends of the surface of tested circular cone by the spherical contact of its front end, can do axially displaced on guiding device.

The described whole micrometric screw parts of spline pin and micrometer that comprise are installed on the L shaped armed lever together, and L shaped armed lever is fixed on the framework by means of screw and conical dowel pin.

A kind of cone shape survey instrument of the present utility model before the measuring workpieces, all is transferred to zero-bit by standard circular cone exemplar with three clock gauges earlier.When in measurement mechanism, laying the circular cone exemplar, must unclamp screw and take out conical dowel pin.Like this, L shaped armed lever just can change 90 ° of pendulum around screw axis, and tested circular cone exemplar is put in the device from right to left gradually, makes the pointer of three clock gauges all be aligned to zero-bit under the situation that turns over a circle.Mobile from left to right then circular cone 0.05~0.10mm, and make it turn back to initial zero-bit state again by means of micrometric screw again, this moment, the reading of micrometer promptly was confirmed as datum readings, and write down measurement result on register.Then, loosen the micrometric screw parts downwards, take out the circular cone exemplar, the tested conical workpiece of packing into.At the reading of writing down on the minute book on all the other two clock gauges and the micrometer, twice difference of reading on the micrometer when adjusting the circular cone exemplar and measuring conical workpiece can be evaluated the error of designing and calculating diameter d.If reading is big for the first time for the second time, just show that tested circular cone d ' is just big than circular cone exemplar d ', vice versa.Difference of reading when the actual numerical value of tested circular cone diameter error can be by measuring workpieces and circular cone exemplar on the micrometer calculates.The difference of reading of first and the 3rd clock gauge can be evaluated the linear value error at circular cone oblique angle.On datum length (promptly by demarcated length) l, the actual size of tested circular cone oblique angle linear value error can calculate according to the difference of reading of the 3rd and first clock gauge.The reading of a middle clock gauge, the shape error of the tested element of cone of decidable, if its read-around ratio zero is big, the bus convexity is cydariform; If its read-around ratio zero is little, the recessed shape of a saddle that is of bus.Can measure the shape of three lateral cross section and two longitudinal cross-sections on the conical workpiece in case of necessity, on two longitudinal cross-sections, measure at least.After each the measurement, measured circle awl half-twist be made, the four measuring result can be obtained like this.Just can determine the flatness error of ovality, the saddle shaped curvature in the longitudinal cross-section, cydariform degree and the bus of conical workpiece in view of the above.By adjusting micrometric screw length, change the supporting contact and the guidance contacts of different length, can measure the cone of different-diameter and length.This measurement mechanism is simple in structure, can measure the error of the whole major parameters of outer conical surface, and has higher measuring accuracy.

A kind of adjustable outer cone survey instrument of the present utility model is compared with prior art has following beneficial effect:

A kind of adjustable outer cone survey instrument of the present utility model during measurement, all is transferred to zero-bit by standard circular cone exemplar with three clock gauges earlier, and this moment, the reading of micrometer promptly was confirmed as datum readings.Then, loosen the micrometric screw parts downwards, take out the circular cone exemplar, the tested conical workpiece of packing into.Determine the flatness error of ovality, the saddle shaped curvature in the longitudinal cross-section, cydariform degree and the bus of conical workpiece according to the difference of reading of 3 clock gauges.This measurement mechanism is simple in structure, can measure the error of the whole major parameters of outer conical surface, and has higher measuring accuracy.

Description of drawings

Below in conjunction with the drawings and specific embodiments the utility model is further specified.

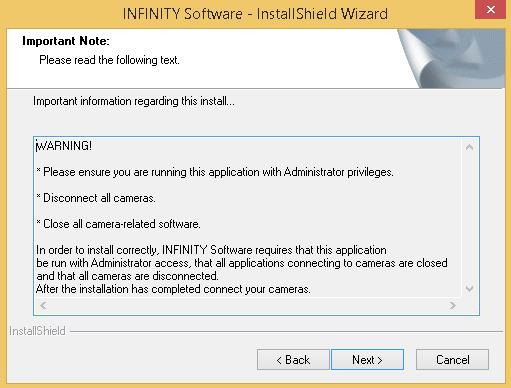

Fig. 1 is the structural representation of a kind of adjustable outer cone survey instrument of the utility model.

Among the figure: support 1, supporting contact 2, framework 3, collet 5, clock gauge 6, micrometric screw 7, spline pin 8, micrometer 9, L shaped armed lever 10, screw 11, conical dowel pin 12.

Embodiment

According to shown in Figure 1, according to shown in Figure 1, this adjustable outer cone survey instrument is made up of support 1, supporting contact 2, framework 3, collet 5, clock gauge 6, micrometric screw 7, spline pin 8, micrometer 9, L shaped armed lever 10, screw 11, conical dowel pin 12.Two knife edge contacts and two guidance contacts with spline structure are arranged on the framework in support, and guidance contacts is installed in and supports contact and become 90 ° side, and the ratio of two guidance contacts mounting distances and difference in height and the installation of supporting contact are consistent; Clock gauge is fixed on the framework by collet.Described framework two ends are connected with the micrometric screw parts, and micrometric screw acts on the both ends of the surface of tested circular cone by the spherical contact of its front end, can do axially displaced on guiding device.The described whole micrometric screw parts of spline pin and micrometer that comprise are installed on the L shaped armed lever together, and L shaped armed lever is fixed on the framework by means of screw and conical dowel pin.

A kind of adjustable cone shape measure instrument of the present utility model before the measuring workpieces, all is transferred to zero-bit by standard circular cone exemplar with three clock gauges 6 earlier.When in measurement mechanism, laying the circular cone exemplar, must unclamp screw 11 and take out conical dowel pin 12.Like this, L shaped armed lever 10 just can change 90 ° of pendulum around screw 11 axis, and tested circular cone exemplar is put in the device from right to left gradually, makes the pointer of three clock gauges 6 all be aligned to zero-bit under the situation that turns over a circle.Mobile from left to right then circular cone 0.05~0.10mm, and make it turn back to initial zero-bit state again by means of micrometric screw 7 again, this moment, the reading of micrometer 9 promptly was confirmed as datum readings, and write down measurement result on register.Then, loosen the micrometric screw parts downwards, take out the circular cone exemplar, the tested conical workpiece of packing into.At the reading of writing down on the minute book on all the other two clock gauges 6 and the micrometer 9, twice difference of reading on the micrometer 9 when adjusting the circular cone exemplar and measuring conical workpiece 4 can be evaluated the error of designing and calculating diameter d.If reading is big for the first time for the second time, just show that the d ' of tested circular cone 4 is just big than circular cone exemplar d ', vice versa.Difference of reading when the actual numerical value of tested circular cone 4 diameter error can be by measuring workpieces and circular cone exemplar on the micrometer 9 calculates.The difference of reading of first and the 3rd clock gauge 6 can be evaluated the linear value error at circular cone oblique angle.On datum length (promptly by demarcated length) l, the actual size of tested circular cone oblique angle linear value error can calculate according to the difference of reading of the 3rd and first clock gauge 6.The reading of a middle clock gauge 6, the shape error of tested circular cone 4 buses of decidable, if its read-around ratio zero is big, the bus convexity is cydariform; If its read-around ratio zero is little, the recessed shape of a saddle that is of bus.Can measure the shape of three lateral cross section and two longitudinal cross-sections on the conical workpiece 4 in case of necessity, on two longitudinal cross-sections, measure at least.After each the measurement, measured circle awl half-twist be made, the four measuring result can be obtained like this.Just can determine the flatness error of ovality, the saddle shaped curvature in the longitudinal cross-section, cydariform degree and the bus of conical workpiece 4 in view of the above.By adjusting micrometric screw 7 length, change the supporting contact 2 and the guidance contacts of different length, can measure the cone 4 of different-diameter and length.This measurement mechanism is simple in structure, can measure the error of the whole major parameters of outer conical surface, and has higher measuring accuracy.

Claims (3)

1. adjustable outer cone survey instrument, it is characterized in that: its structure comprises support, framework, supporting contact, collet, clock gauge, guidance contacts, micrometer, L shaped armed lever; Two knife edge contacts and two guidance contacts with spline structure are arranged on the framework in support, and guidance contacts is installed in and supports contact and become 90 ° side, and the ratio of two guidance contacts mounting distances and difference in height and the installation of supporting contact are consistent; Clock gauge is fixed on the framework by collet.2. a kind of adjustable outer cone survey instrument according to claim 1, it is characterized in that: described framework two ends are connected with the micrometric screw parts, micrometric screw acts on the both ends of the surface of tested circular cone by the spherical contact of its front end, can do axially displaced on guiding device.3. a kind of adjustable outer cone survey instrument according to claim 2, it is characterized in that: the described whole micrometric screw parts of spline pin and micrometer that comprise are installed on the L shaped armed lever together, and L shaped armed lever is fixed on the framework by means of screw and conical dowel pin.CNU2008200209286U2008-04-172008-04-17Adjustable outer cone measuring tool CN201193943Y (en) Priority Applications (1)

Application Number Priority Date Filing Date Title CNU2008200209286UCN201193943Y (en) 2008-04-17 2008-04-17 Adjustable outer cone measuring tool Publications (1)

Publication Number Publication Date CNU2008200209286UCN201193943Y (en) 2008-04-17 2008-04-17 Adjustable outer cone measuring tool Country Status (1)

2008Country Link CN101672618B (en) * 2009-09-21 2011-03-30 江阴江顺精密机械零部件有限公司 Test device for conical surface of outer cone CN102645148A (en) * 2012-04-24 2012-08-22 郑州市钻石精密制造有限公司 Special measuring tool for 10-degree conical surface of HFS-10 handle CN103063183A (en) * 2013-01-11 2013-04-24 洛阳轴研科技股份有限公司 Method of measuring outer diameter tolerance and ovality of thin-walled loop CN109556497A (en) * 2018-11-28 2019-04-02 武汉武船重型装备工程有限责任公司 A kind of detection device and method for stage reel CN101672618B (en) * 2009-09-21 2011-03-30 江阴江顺精密机械零部件有限公司 Test device for conical surface of outer cone CN102645148A (en) * 2012-04-24 2012-08-22 郑州市钻石精密制造有限公司 Special measuring tool for 10-degree conical surface of HFS-10 handle CN102967207B (en) * 2012-11-14 2016-01-20 无锡麦铁精密机械制造有限公司 A kind of outside diameter runout tool CN103063183B (en) * 2013-01-11 2015-06-03 洛阳轴研科技股份有限公司 Method of measuring outer diameter tolerance and ovality of thin-walled loop CN109556497A (en) * 2018-11-28 2019-04-02 武汉武船重型装备工程有限责任公司 A kind of detection device and method for stage reel CN104139317B (en) The datum mark assay method of the titling axis of wire electric discharge machine and mensuration fixture US5111590A (en) Measuring method of machine tool accuracy using a computer aided kinematic transducer link and its apparatus CN201364130Y (en) Planeness measuring device CN205002707U (en) Utensil is tested in special use of rear axle leaf spring bracket aperture centre -to -centre spacing CN101101248A (en) Adjustable clamping device of minisize torsional rod rigidity test CN202119375U (en) Gauge for symmetry degree of shaft key slot CN103822567A (en) Device and method for measuring distance from plate cone gauge section to plate end face of air valve CN105547106A (en) Depth aperture internal diameter measurement device CN203587011U (en) Device for detecting center distance of big head hole and small head hole of connecting rod CN203672259U (en) Shifting fork inspection fixture CN102303266B (en) Special protractor for taper hole CN205209421U (en) Measure specialized tool of hole axiality CN105043190A (en) Five-axis linkage machine tool RTCP dynamic precision calibrating apparatus and calibrating method thereof Legal Events

Granted publication date: 20090211Date Code Title Description C14 Grant of patent or utility model C17 Cessation of patent right We offer a wide range of services, including engineering, high precision machining, and automation.

Our high precision machines enable us to manufacture your requirements with extremely high positional tolerances.

With a large selection of quality inspection machines and tools, we guarantee the best accuracy in North America.

n','url':'https://www.youtube.com/watch?v=PC3EKs9mF3g&feature=youtu.be','width':854,'height':480,'providerName':'YouTube','resolvedBy':'youtube'}'>1210 Markham Rd., Unit 5, Scarborough, Ontario, M1H 3B3

Just a few meters south of Highway 401 on Markham Road.

Phone:

(416) 291 1974Fax:

(416) 291 5011General Info & RFQ's:

vince.micrometric@bellnet.caTechnical/Engineering Queries:

vince.micrometric@bellnet.ca